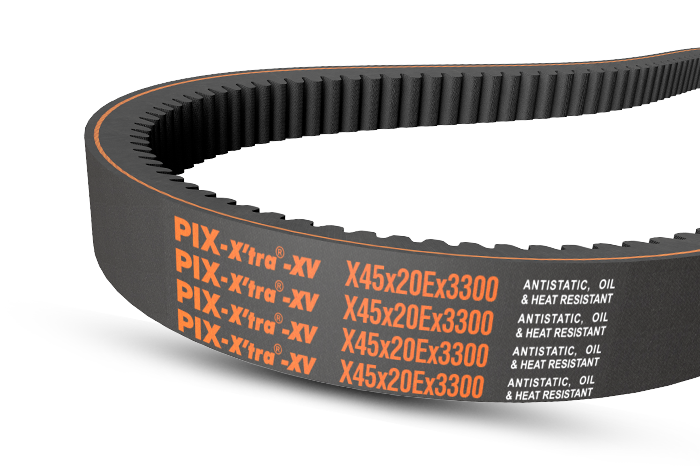

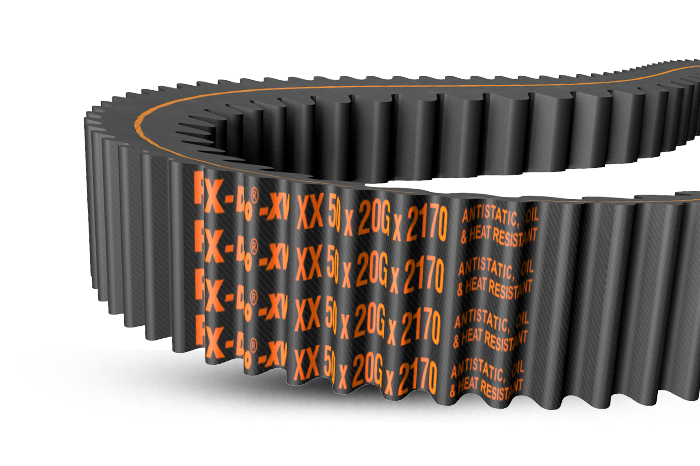

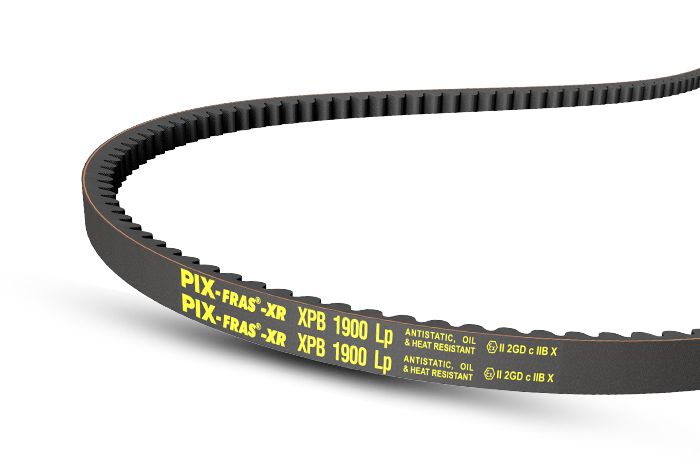

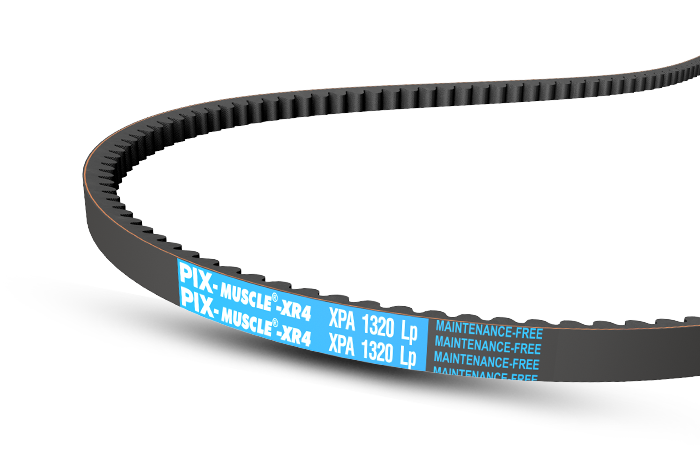

Our product line encompasses a diverse array of sizes and configurations, ensuring that we provide the ideal V Belts solution for every application. Whether your requirements entail heavy-duty machinery or lighter-duty applications, PIX delivers the perfect product to suit your needs.

Constructed from premium-grade materials, our V Belts boast exceptional resistance to wear and tear, enabling them to withstand the most demanding operational conditions. Furthermore, our belts feature precision engineering aimed at minimizing slippage and maximizing efficiency, thereby enhancing productivity and minimizing downtime for your operations.